SOFT SURFACE

HARD SURFACE

APPLIED SURFACES

Through a newly developed test procedure called Repetitive Traffic Scratching (RTS), the performance of a top coat can be demonstrated to show its appearance retention and scratch resistance.

From chairs and tables being constantly pulled across the floor, to sand and dirt on shoes being walked in from outside, ‘micro scratches’ are often the most common issue with resilient flooring today. To prove the performance of ExoGuard+ against micro scratches, our technical team created the RTS test method based off of the Martindale procedure.

Repetitive Traffic Scratching Brochure

View Video

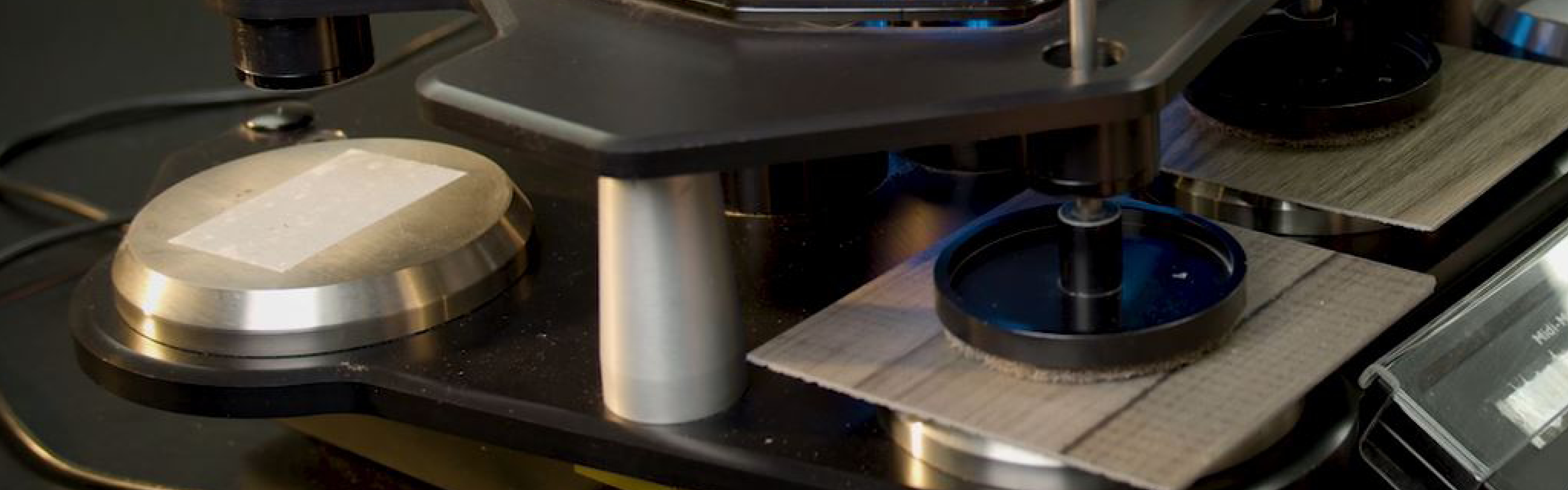

The Martindale Scratch Test Method BS EN 16094 allows for consistent, repeatable and reliable results by using calibrated and standardized weights, abraders, cycles and wear paths. Utilizing this mechanism, we were able to configure the machine and develop a test that would mimic the effects of real life traffic patterns to demonstrate how our products perform.

Repetitive Traffic Scratching Brochure

View Video

After the test is performed, samples are given a numerical rating from 1 to 5 with 1 being absolutely no change in the visual of the product to 5 being heavy, or very noticeable changes in the product.

Patcraft ExoGuard+ styles receive a score of No Change, or No to Slight Change with the RTS test method.

Repetitive Traffic Scratching Brochure

View Video